0512-52430590

0512-52430590

0512-52430590

0512-52430590

SERIES

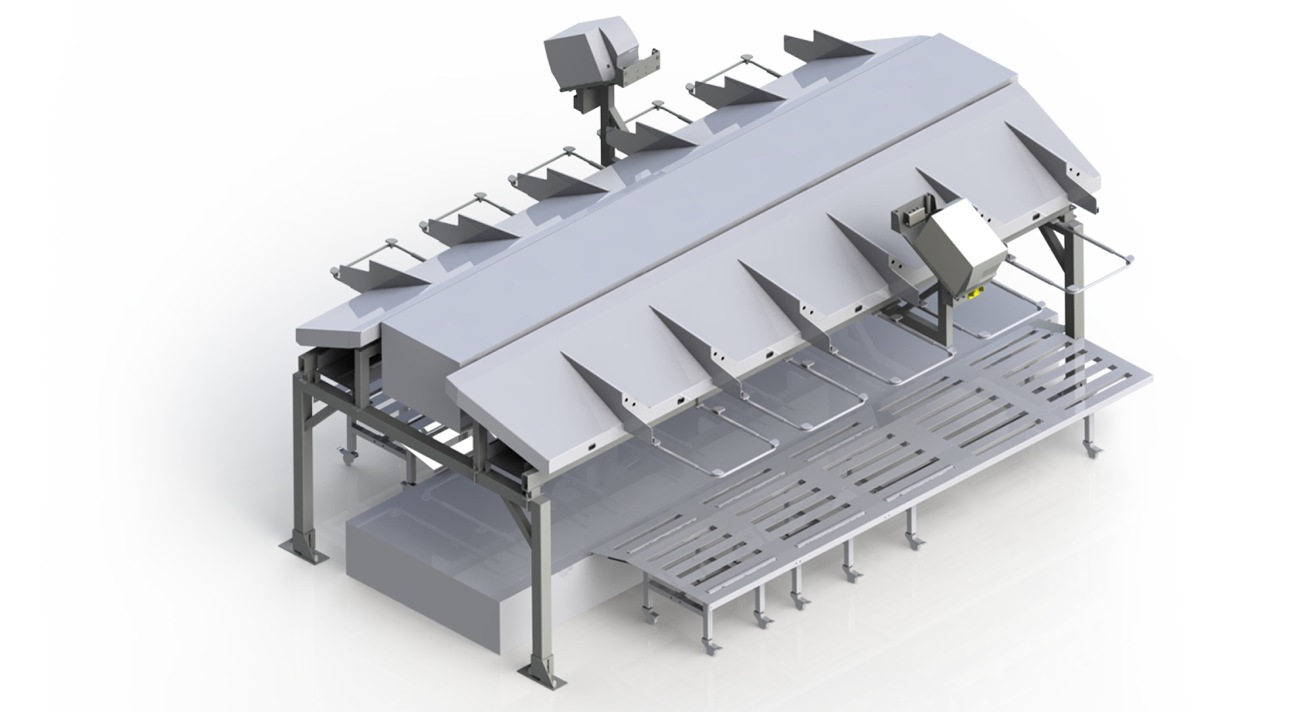

The grid chute is a small piece sorting chute matched with the single-layer cross-belt sorter

Learn More

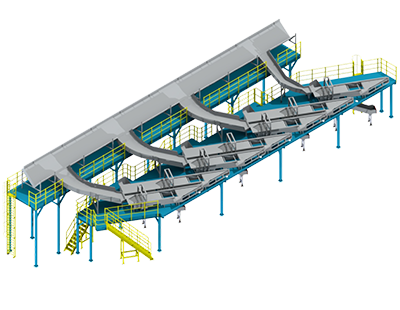

Can be customized according to customer needs, all kinds of light steel, heavy steel and attic storage steel platform, fully assembled structure

Learn More

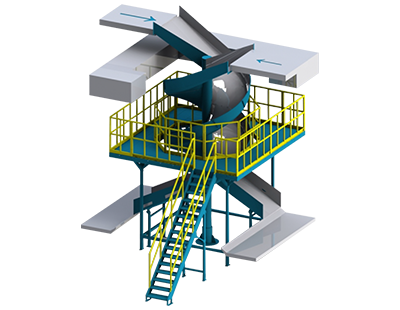

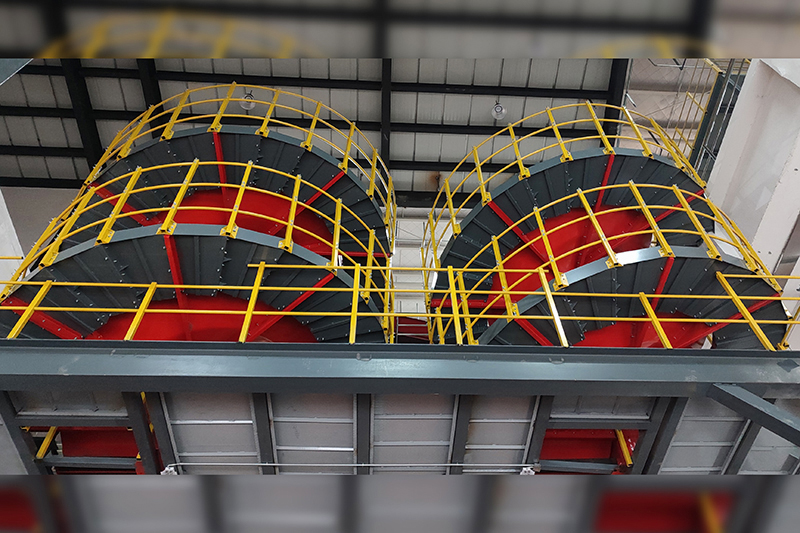

Spiral chute is mainly used for vertical unpowered conveying of material system

Learn More

Jiangsu Yeshen Logistics Equipment Co., Ltd., formerly known as Changshu Yeshen Metal Products Factory, was founded in 2003 and is located in Shanghu Town, Changshu, a beautiful water town in the south of the Yangtze River. It is a high-tech enterprise integrating design, R&D and production with more than 20 years of production experience, providing customers with one-stop logistics system solutions. So far, it has established an international modern production base covering an area of about 25,000 square meters (the third phase of planning), with more than 150 R&D equipment, production equipment, and testing equipment. The company has a team of more than 200 people, including a technology research and development team, who escort the development of the company.

The company mainly produces logistics sorting equipment, steel pallets and other products, and can design and customize various non-standard products for customers. The products have passed the ISO9001:2008 international quality management system certification and international standard certification. Over the years, Yeshen products have been exported to more than 30 countries and regions such as Southeast Asia, Europe, and North America while meeting the needs of domestic customers. It has established strategic partnerships with many group companies.

Since the establishment of the company, it has always been people-oriented and the principle of integrity first has developed rapidly. From pre-sales communication to centralized research and development, design, production, testing, distribution and installation, it adopts one-stop service throughout the process. All employees in this company sincerely thank you for your support and love.

Since 2003

Modern Production Base

Exported to Countries All Over The World

Customer Service

Products

Diamond Chute

Diamond Chute

Small NC Spiral Chute

Three Entrance Spiral Chute

Belt Conveyor Spiral Chute

Maintenance Platform Spiral Chute

Parcel Sorter Spiral Chute

Package Sorting Spiral Chute

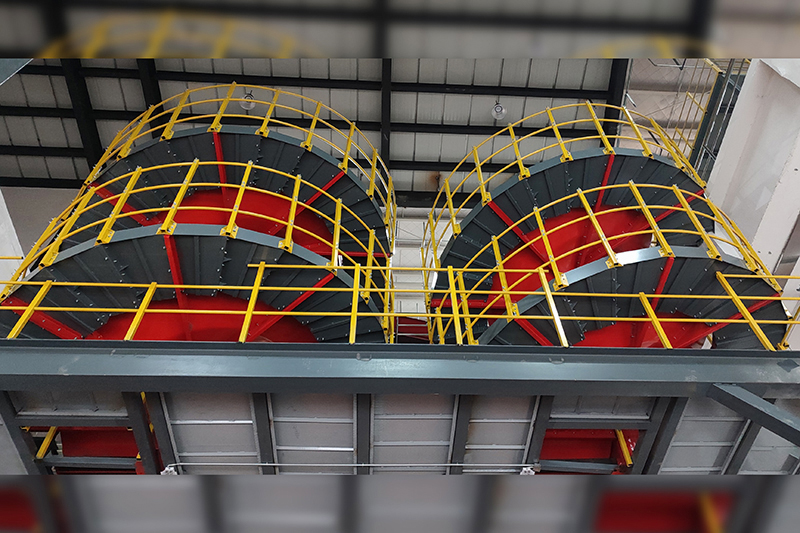

Equipment Steel Platform

Equipment Steel Platform

Equipment Steel Platform

Automatic Matrix Sorting Chute

Clothing Sorting Grid Chute

Double-layer Grid Chute

Small Double-layer Grid Chute

Small Single-layer Grid Chute

Multi-layer Small Pieces Sorting Grid Chute

Small NC Spiral Chute

Three Entrance Spiral Chute

Belt Conveyor Spiral Chute

Maintenance Platform Spiral Chute

Spiral Chute

Fulai Wheel Turning Chute

ADVANTAGE

富有朝氣的研發(fā)團(tuán)隊

設(shè)計中心

智能化的生產(chǎn)基地

質(zhì)量管理保障

Rich technical experience, Won a number of technical invention patents

Every set of logistics sorting equipment in the design center is designed and manufactured

High-quality products lie in the pursuit of details

Strictly implement the ISO9001 quality control management system

partner

Yeshen's products meet the needs of domestic customers while

It is also exported to more than 30 countries and regions such as Southeast Asia, Europe, and North America.

Established strategic partnerships with many group companies

Contact Us >>NEWS

The efficient transmission of small NC spiral chutes relies on the coordination of structural design, material selection, and parameter optimization to enable stable, fast, and low loss sliding of goods by their own weight, while adapting to the irregular characteristics of small and non-standard parts (NC parts).

The core structural feature of the manual matrix sorting chute is "modular combination+layered diversion design". Through standardized chute units, reasonable path planning, and humanized auxiliary structures, it achieves efficient diversion, correct diversion, and safe transportation of goods in manual sorting scenarios, adapting to the sorting needs of small and medium-sized items in industries

The buffering function of the damping deceleration chute is at a relatively high level in the industry, which can achieve smooth deceleration and avoid impact through "gradual adjustment of damping force", especially suitable for scenarios that require correct control of sliding speed (such as logistics sorting and automation equipment).

The drum straight groove (with a core structure of "straight groove body+built-in drum/roller", relying on the rolling of the drum to achieve low friction conveying of materials along a fixed straight line direction, with the functions of "directional guidance" and "efficient transportation") has become the basic equipment for "short distance, linear material conveying" in various industries due t

The grid chute of the product sorting machine (referred to as the "grid chute") is the core conveying component that connects the "sorting execution mechanism" and the "destination grid" in the sorting system. Its "strong compatibility" is essentially achieved through four dimensions: structural design adaptability, material performance universality, functional modularization, and scenario based p

Diamond chutes, with their core advantages of "non powered automatic conveying, orderly sliding of goods, and space saving", are mainly used in the warehousing industry for goods sorting, caching and storage, and inbound and outbound connection scenarios, especially suitable for efficient circulation of small, light and medium-sized goods.

The efficient transmission of small NC spiral chutes relies on the coordination of structural design, material selection, and parameter optimization to enable stable, fast, and low loss sliding of goods by their own weight, while adapting to the irregular characteristics of small and non-standard parts (NC parts).

The core structural feature of the manual matrix sorting chute is "modular combination+layered diversion design". Through standardized chute units, reasonable path planning, and humanized auxiliary structures, it achieves efficient diversion, correct diversion, and safe transportation of goods in manual sorting scenarios, adapting to the sorting needs of small and medium-sized items in industries

The buffering function of the damping deceleration chute is at a relatively high level in the industry, which can achieve smooth deceleration and avoid impact through "gradual adjustment of damping force", especially suitable for scenarios that require correct control of sliding speed (such as logistics sorting and automation equipment).

The drum straight groove (with a core structure of "straight groove body+built-in drum/roller", relying on the rolling of the drum to achieve low friction conveying of materials along a fixed straight line direction, with the functions of "directional guidance" and "efficient transportation") has become the basic equipment for "short distance, linear material conveying" in various industries due t

The grid chute of the product sorting machine (referred to as the "grid chute") is the core conveying component that connects the "sorting execution mechanism" and the "destination grid" in the sorting system. Its "strong compatibility" is essentially achieved through four dimensions: structural design adaptability, material performance universality, functional modularization, and scenario based p

Diamond chutes, with their core advantages of "non powered automatic conveying, orderly sliding of goods, and space saving", are mainly used in the warehousing industry for goods sorting, caching and storage, and inbound and outbound connection scenarios, especially suitable for efficient circulation of small, light and medium-sized goods.

WeChat number:業(yè)神物流設(shè)備

WeChat number:業(yè)神物流設(shè)備